Capturing Reality: How Technology, People, and Planning are Coalescing in the Age of Information

June 26, 2019

There are always unknown factors in construction. As we build in increasingly constrained urban environments or deliver projects that inspire the imagination, unforeseen conditions and complex operations challenge teams to dive deep into the planning process. That’s where reality capture comes in. Reality capture technology, while it sounds futuristic, isn’t far-fetched. Clark teams across the country are leveraging these reality capture tools to build complex jobs smarter and more efficiently than ever.

BALLSTON QUARTER RETAIL RENOVATION

At the Ballston Quarter Retail Renovation project in Arlington, Virginia, Clark’s team collaborated with Clark’s Virtual Design and Construction (VDC) Group to plan and model every single detail in a complex pedestrian bridge move, pick, and installation.

The new Ballston Quarter pedestrian bridge is situated on a major Arlington thoroughfare and connects the redeveloped Ballston Quarter to the Ballston Metrorail station. After working together on multiple iterations of the installation plan, Clark and project stakeholders decided to build the bridge offsite, then transport it and install it overnight.

The pedestrian bridge was fabricated at nearby Mosaic Park, 2.5 blocks from the project site. While this minimized the amount of time required to close the roadway for assembly and erection, it created a challenge in coordinating the bridge move. From planning the pick for placing the bridge on the trailer to determining if existing trees, traffic signals, and buildings would be in conflict with the bridge as it traveled, the project team dove into the details to ensure the smooth execution of the move and installation.

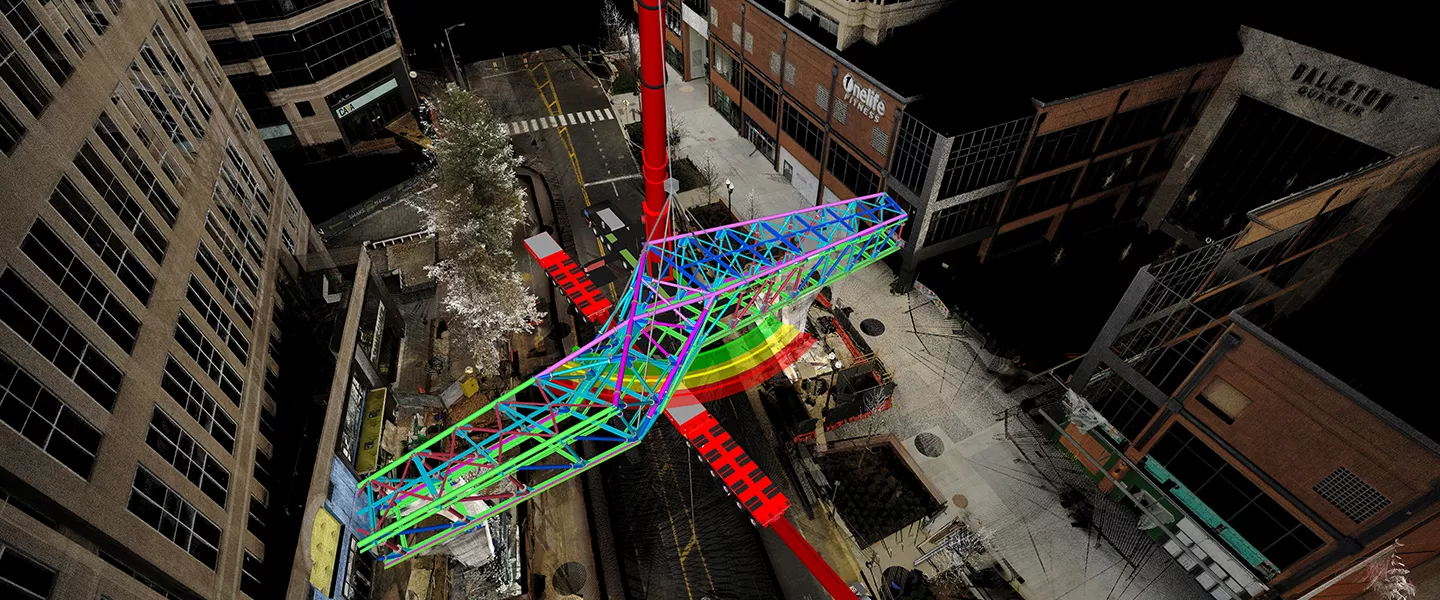

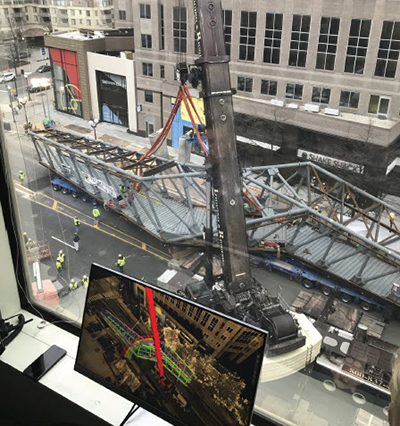

Davin Charlton and John Swagart, Clark team members on the project, worked with VDC’s Shaun Lewis and Eric Liming to plan every inch of the complicated operation. Lewis and Liming utilized 3D laser scanning to create accurate point clouds that digitally recreated not just the installation, but also the entire path of the bridge from Mosaic Park to its final resting place – down to the tiniest detail. They collaborated with the onsite team to develop a plan that would take into account the trailer’s turning radius, the location of underground utilities, and critical clearances to make sure the bridge could be moved and installed without a hitch.

The team then modeled the crane set up in relation to the bridge to minimize the amount of movement and confirm proper weight distribution. They created as-built conditions and walked through the entire move and installation from start to finish, checking for everything and anything.

The planning paid off.

During the modeling process, Liming discovered that a 30-foot ledge on a building to the north of the bridge was critical to clear for proper installation. This discovery required a very specific crane model to achieve the required clearance while maintaining the load distribution at grade.

“If you can’t do it on paper, then you can’t do it in real life,” commented Ryan Flaherty, Clark senior project manager. “This model was critical. It taught us that, based on real conditions, we had to carry out this installation in a very exacting way. There were so many little precise movements in the crane operation to pivot the bridge into place, and we had to use a very specific piece of equipment for it to work.”

The Ballston pedestrian bridge began its journey from Mosaic Park to its permanent location starting at 8:00 p.m. on February 15. The bridge was transported from Mosaic Park on a 16-axle self-leveling platform trailer, and was lifted into place by a Liebherr LTM1500 crane.

Without a hitch.

THE BIG PICTURE

The Ballston pedestrian bridge is just one example of how Clark is using reality capture to better plan and execute work in the field. VDC’s team has partnered with Clark’s Field Engineering Group on a number of laser scanning projects, including Midtown Center, the International Spy Museum, and CSX Virginia Avenue Tunnel.

In addition to laser scanning, Clark’s team is expanding in-house capabilities to take project planning and documentation to new heights. Every day at the North Torrey Pines Living and Learning Neighborhood (NTPLLN) site, licensed pilots fly drones over the 34-acre UC San Diego project site to capture hundreds of aerial photos. The images are processed to produce high-resolution orthomosaic photos and 3D point cloud data, effectively creating a repository of useful and accessible information.

“A key benefit of drone data is the enhanced progress documentation it provides to the entire project team including our clients, architects, and trade and consultant entities. Via a web interface, the team can view and compare 2D and 3D data collected on different dates, create overlays, and take 2D/3D measurements,” explained Clark VDC Manager Ali Kashani. “The daily aerial views also give all the project entities – even those that are not physically present at the site – an overview of the project progress,” he adds.

Drone data has been useful for logistics planning, quality control of underground utilities, and tracking excavation productivity. The ability to overlay drawings on top of aerial photos and check the elevations and coordinates alongside drone data helps the team confirm that the work going in place is correct and on schedule.

“There is a large spectrum of technologies that all contribute to reality capture in construction,” explains Shaun Lewis, Clark's senior reality capture manager. From 360-degree cameras to imaging laser scanners, the industry is rapidly evolving and experimenting with technology to build smarter, and safer.

“For me,” comments Lewis, “Clark’s reality capture program is drilling down to the details a lot more than other programs out there, and it’s making all of the difference. On complex jobs like the Ballston Quarter bridge installation, you need to know that your team has accounted for every possible detail and reality capture helps them do just that.”

THE NEXT GENERATION

In addition to cultivating Clark’s in-house expertise, the VDC team is dedicated to preparing the next generation of field leaders to take advantage of and recognize the possibilities of reality capture and the larger umbrella of Virtual Design & Construction.

In 2018, VDC began a rotational program in which engineers spend three months in the VDC Group learning the technology and producing project-specific deliverables. After completing the program, engineers return to jobsites with a deeper knowledge of Clark’s VDC capabilities and the expertise to leverage them onsite.

This program is fostering a coalition of field leaders with an understanding of how to harness technology and combine those resources with the knowledge of people in the field.

“VDC is a huge resource for the company and our clients. It pays its weight in gold to sort out issues ahead of time and account for other options, rather than making those costly discoveries the day of an operation,” comments Swagart. “But reality capture and VDC isn’t a magic wand. Project teams find the most successful results when they combine their knowledge of project requirements and site constraints with VDC’s expertise. The magic happens when our VDC team collaborates hand-in-hand with the experts on the ground.”