Client

Massachusetts Convention Center Authority

Designer

HNTB Architecture

Rafael Viñoly Architects

Location

Boston, Massachusetts

Size

1.7M Square Feet

Completion Date

2004

Delivery Method

Construction Manager at Risk

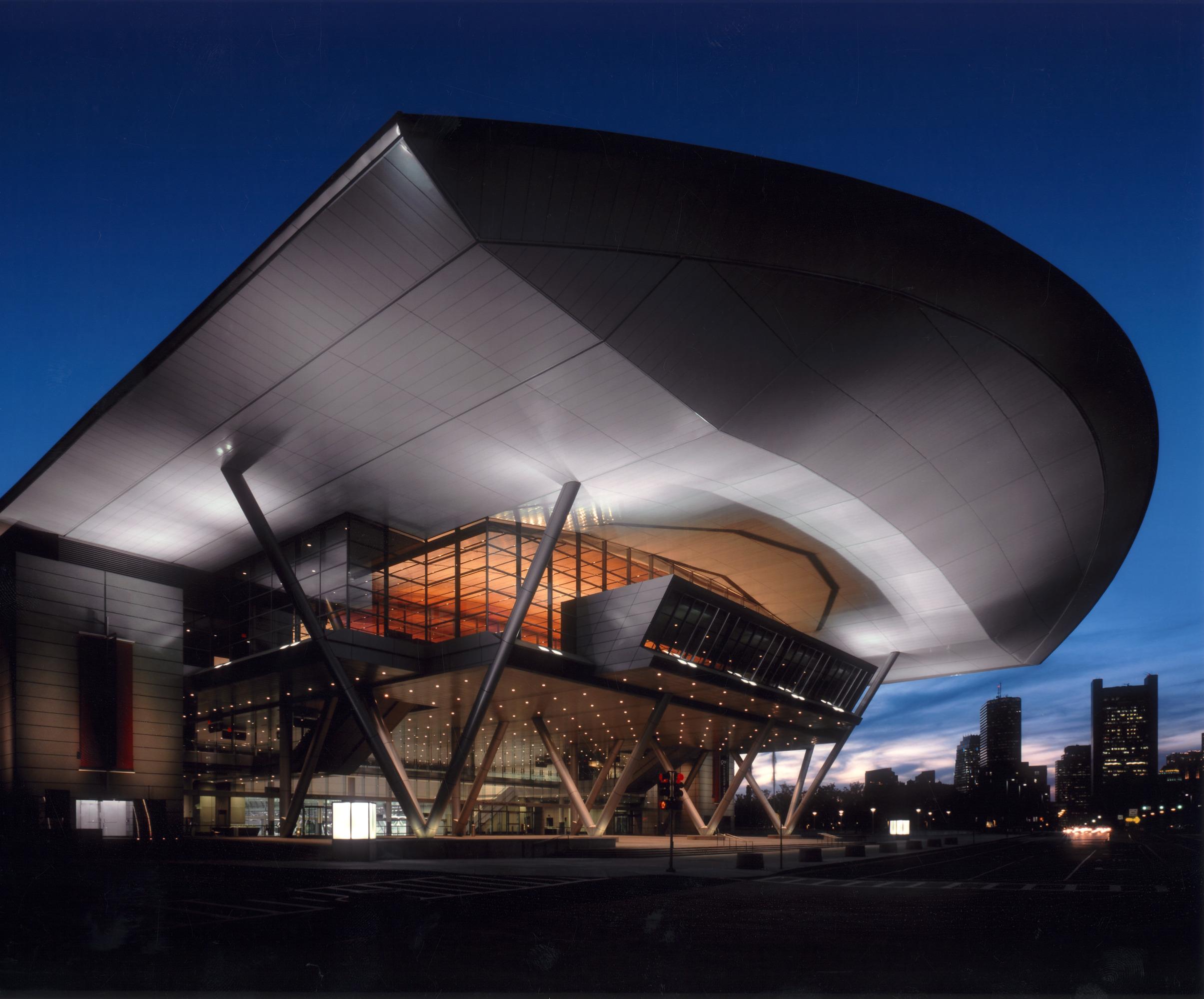

Boston Convention and Exhibition Center is a 1.7 million-square-foot building featuring an exhibition hall, ballroom, and meeting rooms. The property features 2,000 parking spaces, ancillary space, and state-of-the-art audio-visual capabilities.

Awards

2005 AGC of Massachusetts Build New England Award (Honor)

2005 Building Design + Construction Building Team Award (Specialty Space)

2005 Metal Construction Association President Award (Overall Excellence)

2005 AISC National Design-Build Award (Merit, Innovative)

2005 International Design Association Award (Interior)